What Is Metal Shearing?

It’s a process that involves cutting large pieces of metal to meet specific dimensions required for your project, making the material manageable and ready for further processing.Shearing typically requires specialized machines, like shears or guillotine cutters.

The shearing process involves placing a piece of metal between two blades. One or both blades moves downward, applying pressure to shear the metal. The shearing blades are usually high-strength steel alloys or tungsten carbide. This method can handle various materials, including steel, aluminum, and copper, and it can be adapted to different thicknesses and types of cuts.

Types of Metal Shearing:

* Straight shearing: involves making simple, linear cuts, typically used for cutting metal into rectangular or square shapes.

* Contour shearing: allows for more intricate and complex cuts.

Mechanics of Metal Shearing

Primarily involve the role of the blades and cutting edges. The shear blades have specific angles and edges facilitating the cutting action. When the shearing machine mechanism applies pressure, the blades generate a shearing force that penetrates the metal, separating it along the intended line.

Material Characteristics

The properties of the metal you work with greatly impact the shearing process. Knowing the material’s properties lets you select the appropriate tools and settings for a successful shearing process. Hardness, ductility, and thickness affect how the material behaves during shearing. For example:

* Harder materials: require more force to shear and could lead to increased tool wear.

* Ductile materials: can deform rather than shear cleanly, so adjust the shearing parameters accordingly.

* Thicker materials: require stronger, more durable blades that can cut through them and not dull or break.

Environmental Impact

By adopting environmentally friendly practices, your operations can align with industry standards and consumer expectations, fostering a positive brand image while contributing to global sustainability efforts.

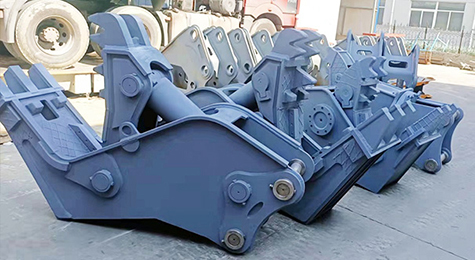

XINPU Hydraulic Double Cylinder Shear is particularly well-suited for the recovery of robust metals such as steel plates and steel bars. It operates through a hydraulic system and features a dual-cylinder design, providing enhanced cutting force and efficiency. This equipment is commonly used for cutting metal sheets, profiles, or pipes, offering traits of speed, precision, and high efficiency.

Features

* Applicable to high-altitude shearing and demolition.

* Double-spindle design, strong shearing force.

* The oil cylinder protection cover is easy to disassemble and install.

* Alloy inserts have strong cutting force and good performance.

* Blade guidance prevents waste-plugging outbreaks.

* 360°rotation, straight feeding is easier.