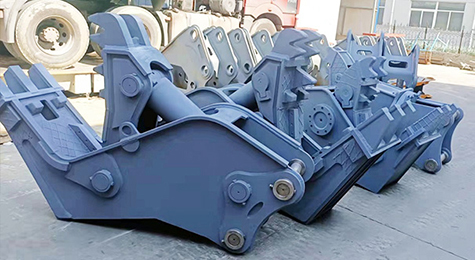

Important Facts About XINPU Scrap Lifting Magnets

All lifting magnets operate using the same fundamental laws of physics. Magnetic power is often pictured as lines of magnetic force flowing from north pole to south pole. Anything that limits the flow of these magnetic lines of force reduces the magnet’s lifting capacity.

There are many important factors which limit the flow of these lines of force.

- LOAD THICKNESS

The greater the number of lines of magnetic force flowing from a magnet into the load, the greater the effectiveness of the magnet. The thicker the load, the more lines of magnetic force are able to flow. Beyond a certain thickness of load, no additional lines of force will flow because the magnet has reached its full capacity.

- SURFACE CONDITIONS

Magnetic lines of force do not flow easily through air; they need iron in order to flow freely. Therefore, anything that creates a space or an air gap between a magnet and the load limits the flow of magnetic lines of force, and thus reduces the lifting capacity of a magnet.The lifting surfaces of a magnet must be clean, smooth, flat and free of nicks and burrs to minimize the air gap between a magnet and the load. The scrap lift magnets have been designed with soft, low carbon steel lifting surfaces in order to maximize the lifting capacity; special care must be taken to protect these surfaces.

- LOAD ALLOY

Low carbon steels, such as SAE 1020 steel, are nearly as good conductors of magnetic force as pure iron. However, many other alloys contain non-magnetic materials which reduce the ability of magnetic force to flow into the load. An alloy such as SAE 300 series stainless steel is almost as poor a conductor of magnetic force as air.

- LOAD LENGTH OR WIDTH

As the length or width of a load increases, it ceases to remain flat when lifted and the edges begin to droop. This drooping or sagging of the load can create an air gap between the load and the magnet. This is called peel; if peel occurs, the lifting capacity of the magnet is greatly reduced.

- POSITION OF MAGNET’S LIFTING SURFACE

As the position of the magnet’s lifting surface changes from horizontal to vertical, the lifting capacity of the magnet decreases. When the magnet’s lifting surfaces are vertical, the lifting capacity of the magnet is minimized and dependent upon the coefficient of friction between the magnet’s lifting surface and the load.

- PORTION OF MAGNET SURFACE IN CONTACT WITH LOAD

The full surface of the magnet must contact the load if the magnet is to achieve rated lift capacity.

- LOAD TEMPERATURE

The temperature of the load can cause damage to the magnet.