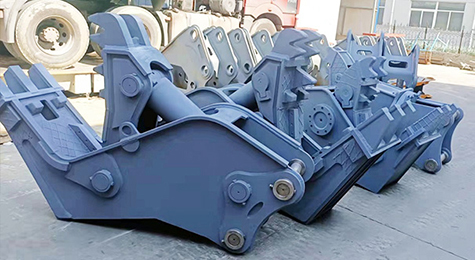

Olecranon shear model features

Excavator nose scissors, suitable for installation in 28-40 tons of brands of excavators, suitable for steel structure workshop demolition and scrap truck dismantling, can cut most of the steel and heavy vehicle frame dismantling shear. The cutting speed varies with the size of the excavator, which is 8-15 seconds to complete a cutting.

Olecranon scissors are divided into M type and A type. The M-type is hydraulically driven rotary model, and the rotation Angle of the shear head is controlled by the driver; Type A is a free rotating model, without rotary drive, shear head 360 free rotation, suitable for cutting ground materials and scrap vehicles, need to be driven by a skilled driver, the working speed is twice as fast as the M type.

In addition to the normal forearm connection mode, there is another big-arm connection mode. In the case of the big-arm type, the excavator's forearm is removed when the excavator's tonnage is small, but the work demand is large, and the larger beak scissors need to be installed, and the beak scissors are directly installed on the big arm of the excavator. The advantage is that large beak scissors can be installed on the excavator with smaller tonnage. The disadvantage is that the working radius is small, and it is not suitable for the work of cutting height.